About Our Work

Turbomachinery are one of the core technologies for most traditional and green power generation systems such as fuel cells (clean air/gas delivery systems), micro gas turbines (MGT) with various fossil and bio fuels, winds, and solar-thermal systems. Especially, microturbomachinery with power range below 1MW have broad applications not only in power generation systems but also in unmanned aero propulsions, automotive applications (turbochargers and electric turbo compounds), and gas processes.

Research Projects

Our research projects include:

- Design of small oil-free gas turbines for UAV propulsion and power generation,

- Advanced thermal management method of electric motors for hybrid vehicles,

- Micro gas turbines for residential CHP boilers,

- Non-contact gas bearings, and

- Compliant surface seal.

Engineering Service and Foil Bearing Development

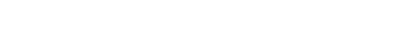

Core competency of our team is thorough knowledge and know-how on manufacturing process of foil bearings and their operating characteristics.

Environment-Friendly

One of the research thrust areas in our lab is to develop core technologies for environment-friendly microturbomachinery. Main effort is on developing air foil bearings (AFB) and tilting pad gas bearings for environment-friendly microturbomachinery. One of the technical challenges associated with adoption of AFBs is a thermal management of the bearing. Even if main advantage of the AFB is a low friction, heat generation inside the bearing and relevant bearing failure mechanism cannot be overlooked. Current research activities on AFB include: development of computational model to predict thermal instability of rotor-bearing system and experimental verification; design and testing of 4” dia hydrostatic air foil bearing; development of micro fuel cell blower with 5mm dia air foil bearing. Both experimental and computational works are performed in our lab.

Solid Oxide Fuel Cell

Another thrust area is to develop multi-scale/multi-physics computational model of Solid oxide fuel cell (SOFC) system including stack, heat exchangers, auto thermal reformer, and blowers for air delivery and anode exhaust recirculation.

SOFC systems have been recognized as the most advanced power generation system with the highest thermal efficiency with a compatibility with wide variety of hydrocarbon fuels, synthetic gas from coal, hydrogen, etc. Currently, detailed non-linear thermal dynamic models of cross-flow gas-gas heat exchangers and planar SOFC stack have been developed and experimental verifications are underway.